Research

Polymers and Nanoparticles

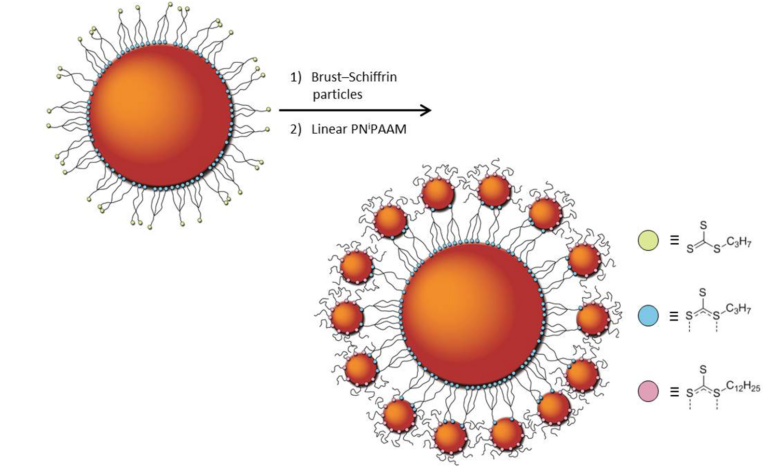

In order to expand the flexibility of our nanoengineering toolbox, we explored and used silica nanomaterial as additional platform for nanocomposites. By further optimizing and adapting the rather mature silica chemistry, we were able to fully integrate this material – which often has properties that are complementary to those of noble metals – into our building block strategies. We used silica to coat various NPs in order to adapt the surface properties of metal for polymer and solvent interaction and for providing an optimum surface for surface-initiated polymerization, which we have explored extensively. We were, e.g., able to coat palladium nano-cubes with a mesoporous silica shell, which improved the corresponding catalysis process, we were able to coat magnetite NPs with silica, by which we could reduce disturbing magnetic interaction phenomena,

and we could cover polymer particles that are filled with either gold NPs or magnetic NPs with protecting silica shells.

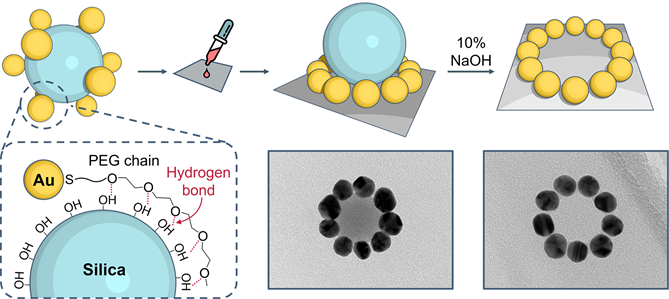

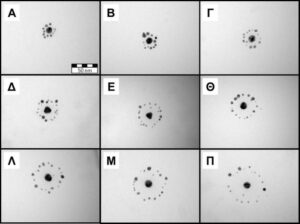

We also developed a novel strategy to easily form precise ring-shaped arrays of AuNPs by polyethylene glycol-(PEG)-grafted AuNPs, that were attached to silica NP cores via hydrogen bonding in a controlled fashion, forming well-defined core–satellite structures in colloidal solution. The attached gold NPs show unique surface mobility on the silica core surface, which allows for NP rearrangement into a 2D ring pattern surrounding the silica NP template when the core–satellite structures are cast to a planar surface. When etching away the silica core under conditions, in which the polymer shell fixes the satellites to the substrate, highly ordered ring-shaped patterns of AuNPs were formed.